SOLAR CELLS WITH PERC TECHNOLOGY

WIR LÖSEN IHRE ANFORDERUNGEN

HIGHLY EFFICIENT SOLAR CELLS WITH PERC TECHNOLOGY

Solar wafer technology has, of course, been developing steadily for years. And, in particularly dynamic photovoltaic markets like China, solar wafers manufactured using innovative methods like PERC are already being used on a massive scale. Wafers manufactured with the PERC method currently offer a conversion efficiency more than 20% higher than that offered by conventional BSF or HIT solar cells. The International Technology Roadmap for Photovoltaics (ITRPV) predicts that PERC solar cells will have a global market share of more than 70% in 2026 – and laser technology plays a crucial role in this production technique.

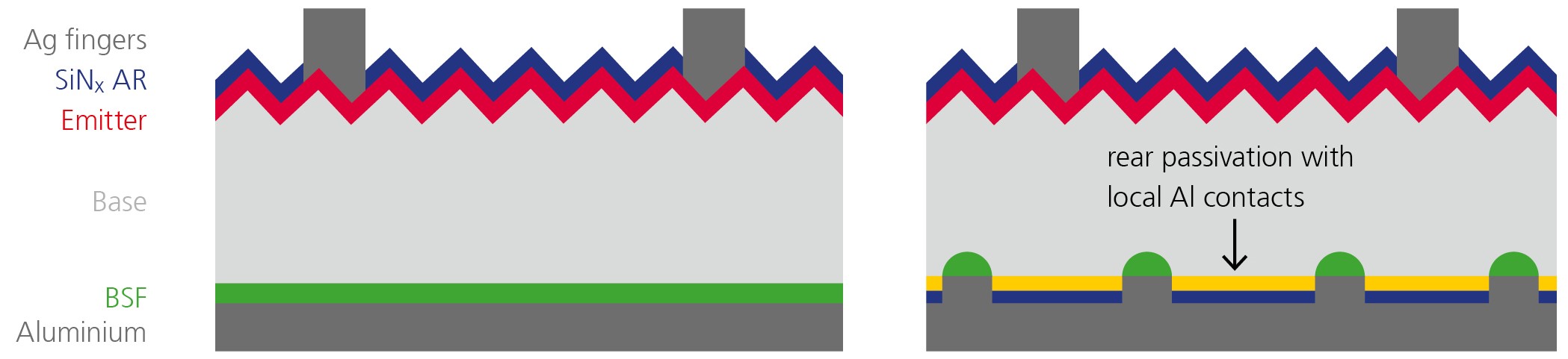

In the PERC production process (Passivated Emitter Rear Contact), greater energy conversion efficiency is enabled by a dielectric passivation layer (usually Al₂O₃, SiO₂, SiNx). This reduces the recombination of electrons at the rear surface of the solar cell, where the electrons would otherwise experience a strong attraction to the aluminium layer. As a result, more electrons reach the front emitter and the current density is increased.

The process known as Laser Contact Opening (LCO) represents an important step forward in the manufacturing of PERC cells. It uses laser ablation to create contact openings in the rear passivation layer. The focus is on the selective removal of passivation layers by means of a dash, dot or line pattern. Typical methods for opening the rear of the cell include mechanical marking or wet-chemical etching. Neither of these methods is feasible in terms of speed or waste production – with wet processes in particular leading to a high degree of contamination. The laser process is therefore ideal for selective, contact-free removal of the layer. However, these new solar technologies also present challenging requirements for the entire solar wafer manufacturing process.

THIS RAYLASE SOLUTION ENSURES A HIGH THROUGHPUT OF UP

TO 3,600 WAFERS PER HOUR WITH CONSISTENTLY HIGH QUALITY.

The SUPERSCAN IV-SOLAR is very flexible. If one would like to scribe the wafer fast and precise, a so-called Skywriting control function can be activated. With this feature, the scanner does not need to accelerate or decelerate during scribing process thus resulting equidistance pulses at the beginning and end of the line. In addition, the

scanner does not need to slow down at the “window” openings in the passivation layer, the scanner jumps over them, therefore avoiding wasting time unnecessarily. We can merge the line segments into a single line so that no deceleration or acceleration occurs at the “windows”. In this case, we use the “dashed-line” feature so that the laser is only modulated in the relevant places.”

Another advantage is the optimal interplay between the SUPERSCAN IV-SOLAR deflection unit and the SP-ICE-3 control card from RAYLASE. The SP-ICE-3 enables control of two deflection units and therefore has two field transformations that can be used to mark two wafers with an identical layout simultaneously but with different orientations on the carrier.

Many industries with various application scenarios can benefit from this capability of our RAYLASE solution. Although we developed SUPERSCAN IV-SOLAR for the solar market, the product is not limited to this industry alone. Our solution can be implemented for any application, such as laser material ablation, that requires high speed and a high degree of precision.”

The 2-axis SUPERSCAN IV-SOLAR deflection unit is designed to meet the rigorous performance requirements that apply to high-speed, high-precision laser processing of solar cells because this particular application requires the highest possible positioning speed.

The SUPERSCAN IV-SOLAR’s digital control offers maximum speeds of up to 50 m/s final speed. The robust, water-cooled master block design enables applications at up to 2 kW laser power. And, with the SP-ICE-3 control card and the corresponding software from RAYLASE, you are perfectly equipped to control the deflection units via SL2-100 protocol 20 bit or XY2-100 protocol 16 bit.

RECOMMENDED RAYLASE SOLUTIONS

- High speed scanning up to 50m/s with the SUPERSCAN IV-SOLAR

- Precise control of deflection units via SP-ICE-3 CONTROL CARD

- The software solution for Dashed-Line and Sky writing feature : RAYGUIDE

RAYLASE worldwide

Get expert advice for your application

Further applications