Welding copper - blue diode laser

Clever laser systems facilitate production in electromobility

Intelligent laser systems facilitate production in electromobility significantly. Blue Laser+deflection unit are ideal for welding thin copper sheets

A blue laser is a laser that works with electromagnetic radiation in the wavelengths range between 360 and 480 nanometres. The light is perceived as blue or violet by the human eye. Since the beginning of the century, advancements in semiconductor laser technology and the development of Direct Diode Lasers (DDLs) have brought the blue laser into industrial production. The “Century of Light” brought enormous progress to the development. Today, the new generation of high-speed is setting out to revolutionise the still juvenile field of electromobility: Diode lasers with 445 nanometres and 2000 Watts of laser power, for example, combined with special opto-mechanical laser deflection units offer an environment-friendly, fast, and high-quality splatter-free solution in confined spaces. Such laser systems achieve unsurpassed results especially when welding the smallest of copper components.

Copper is the most important material in the transmission of electrical signals and is therefore the key component in electromobility. Whether in battery cells for mobile terminal devices, in induction coils or batteries of electric cars – copper contacts can be found everywhere today. The components are often subjected to high voltages, high operating temperatures, and severe vibrations here. This has a decisive influence on the manufacturing process: If the components are assembled from numerous parts, the joining seams must have a high stability and must not produce any additional resistance in the signal flow, so that the full conductivity can be harvested.

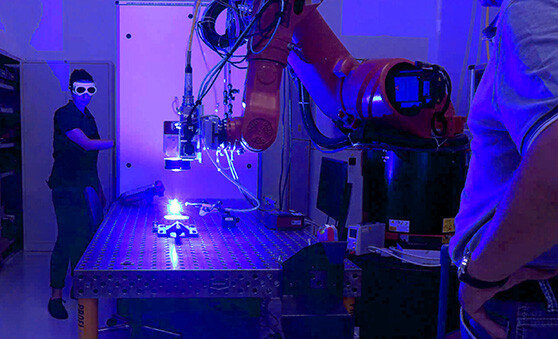

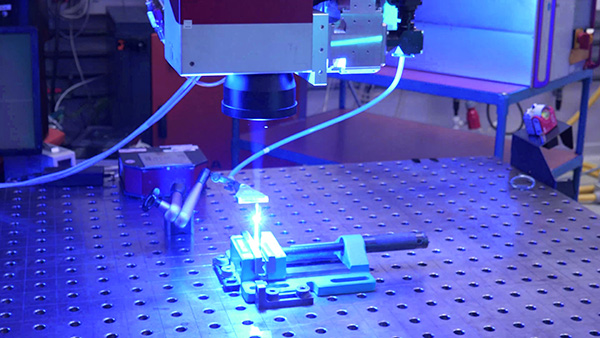

Here, the welding of hairpins is tested using a laser system consisting of a blue diode laser from Laserline combined with the SUPERSCAN IV-30 deflection unit from RAYLASE. Source: Laserline.

The industrial laser radiation sources in the infrared range available to date dictated additional effort and costs in order to process copper satisfactorily in a series production environment. “Our LDMblue blue diode laser was ideal here; the first blue industrial laser worldwide in the multi-kilowatt range from Laserline. Also in combination with the SUPERSCAN IV-30 from RAYLASE, it opens us an alternative system solution for laser-processing of material, with entirely new possibilities, particularly for battery manufacturing too,” Dr. Simon Britten, Technology Manager at Laserline states emphasising the new options for the industry. Thus, low reaction times and moderate energy inputs were indispensable particularly for wafer-thin copper wires and pins as well as for very thin foils, like those needed in battery

manufacturing. Because high intensities would sever the copper foil immediately. However, as the infrared laser requires higher intensities to melt copper, intricate copper components and non-ferrous metals are processed much more effectively with the blue laser.

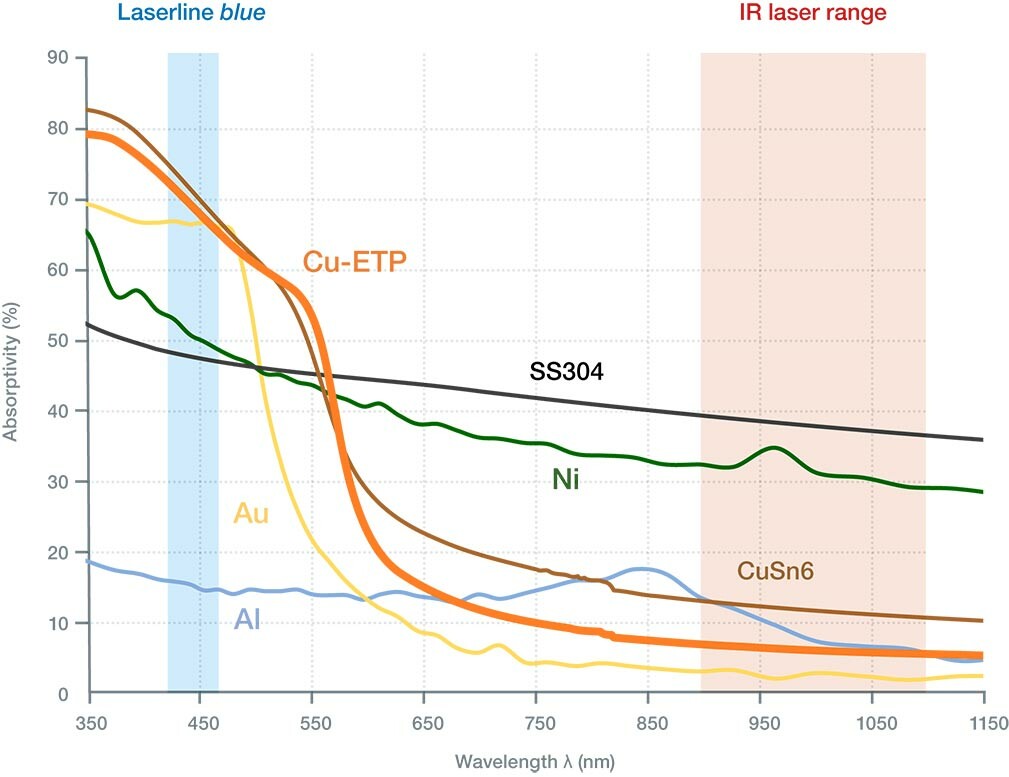

And a further property of the material poses an additional challenge: Copper absorbs the blue light spectrum above 50 percent, unlike standard infrared radiation, which

only reaches 5 percent, as the graphic included shows impressively. For this reason, weld seams produced using the blue wavelength together with the fast modulation and deflection of the laser beam are an excellent choice for many applications in electromobility.

Copper (the red line CU) has a radiation absorption of more than 50 percent in contrast to the infrared range (IR) of only 5 percent in the blue wavelength range at room temperature. Graphic from Laserline video / Source Laserline.

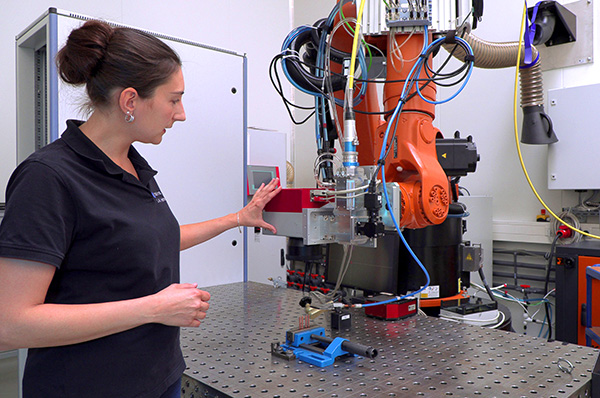

New welding processes are tested and developed in Laserline’s application lab. Here, you can see the laser system with the RAYLASE deflection unit.

From the vision to the innovation

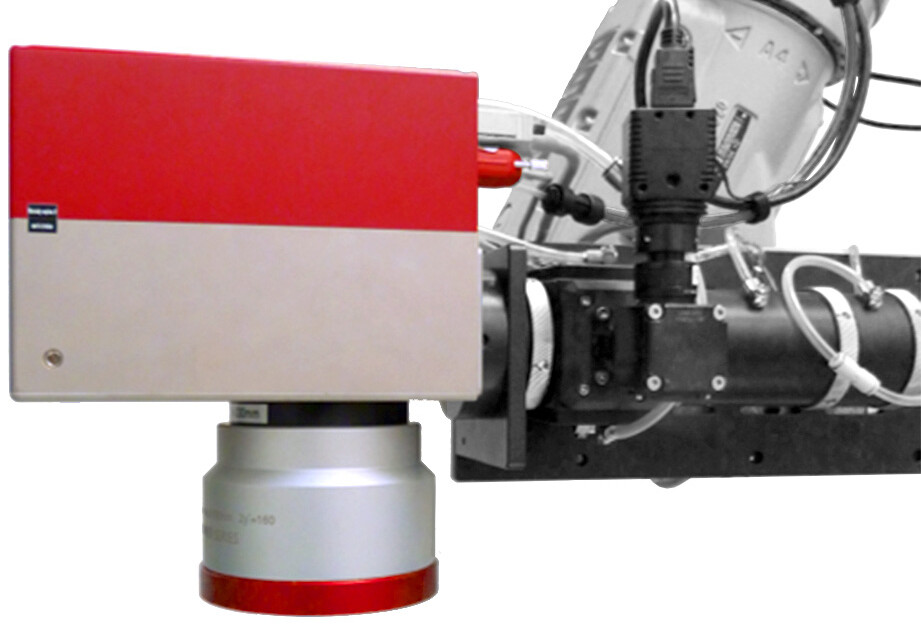

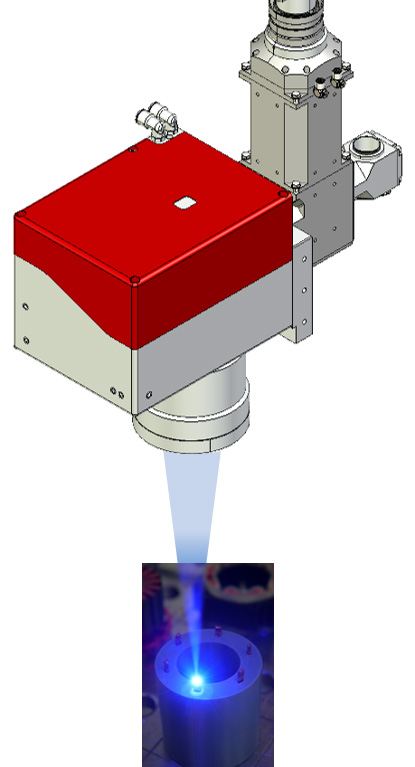

The high-power diode laser from the industrial laser manufacturer Laserline + the SUPERSCAN IV-30 deflection unit from RAYLASE with specialised optics are ideally matched for welding copper in battery manufacturing.

The new laser system sustainably supports the industry on its path towards fast, precise, and economical working processes for mass production. The following manufacturing steps profit especially: When welding copper contactsof small electric motors, which are often required in the automobile industry for electric seat adjustments, windscreen wipers, electrically operated windows, boot

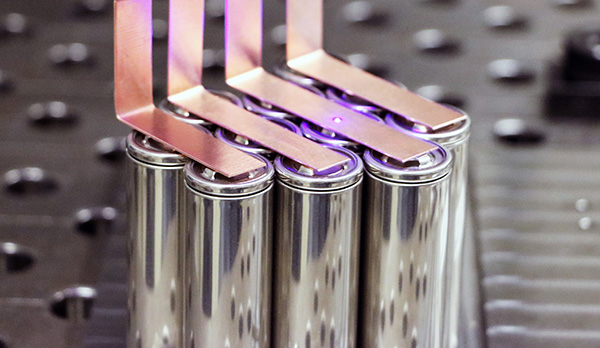

lids and much more. When welding thin copper sheets to pack bars in the power electronics and when joining copper contacts for high-power connectors and/or when welding cell connectors of the copper tabs in battery cells.

Many small electric motors profit from the blue laser wavelength range in combination with a specific deflection unit. Source: Laserline.

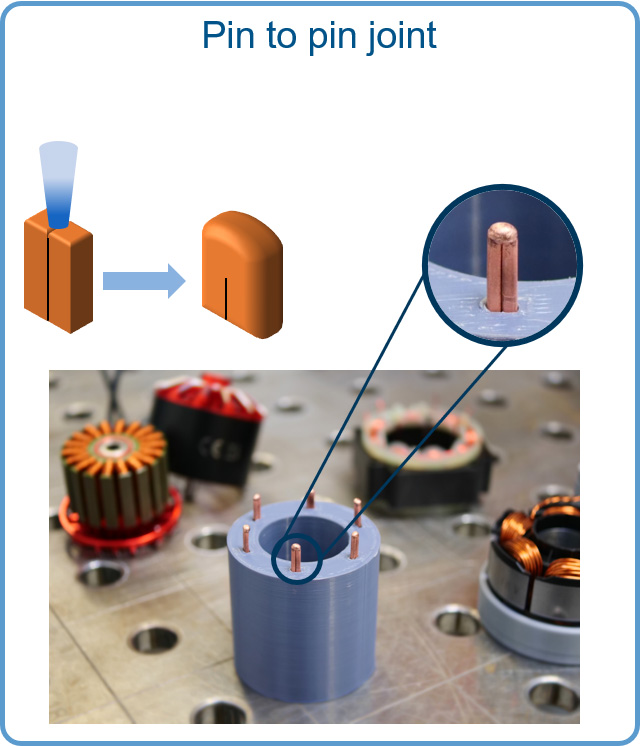

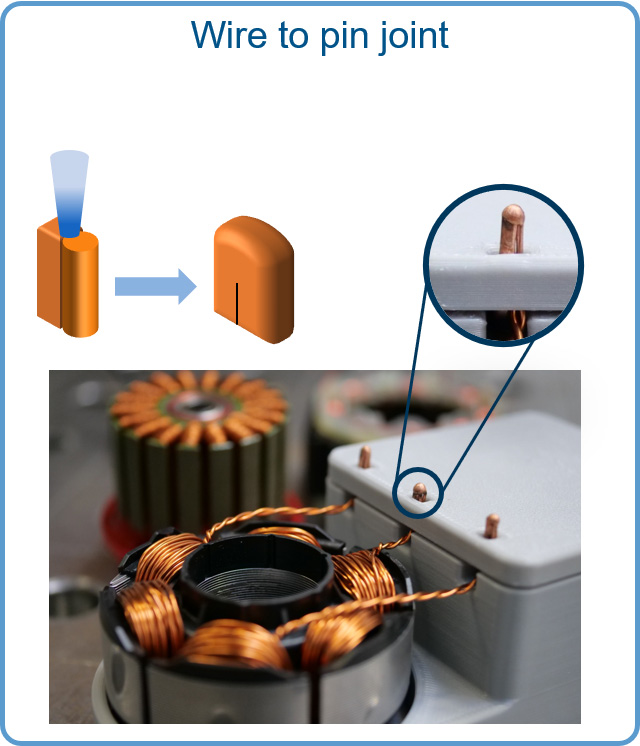

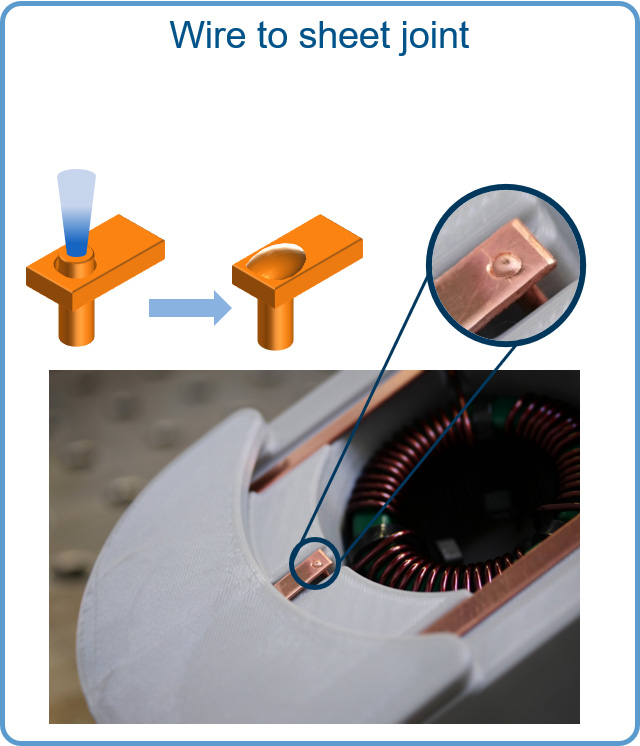

The different joining configurations for welding electrical contacts

Pin to pin joint

Wire to pin joint

Wire to sheet joint

Besides the high absorption of blue light, which significantly facilitates the melting of copper in the electromobility sector, the use of the typical intensity profile of the diode laser and the corresponding digital opto-mechanical deflection unit also contributes to the good processing result.“Our proven diode technology allows a fine-graduation for the regulation of the laser power with the blue laser within milliseconds and thus an optimal adaption to process requirements. The high absorption of the blue wavelength in copper allows comparatively large spots, which achieves well controllable thermally conductive welding processes with almost splatter-free and pore-free results, regardless of the surface properties of the material prior to the welding process. Furthermore, the high surface tension of the liquid copper in combination with the large spot also bridges gaps. This allows the implementation of very robust welding processes with simultaneous acceptance of component tolerances”, Mathias Schlett, Key Account Manager Laserline, enumerates the numerous functions of the blue laser.

Welding copper busbars at cylindrical battery cells to manufacture battery modules Source: Laserline

Werner Grünwald, who has been active in Sales at RAYLASE for 17 years and is responsible for Laserline, praises the year-long established business relationship between the companies. “Each of us reaches out to the other to drive innovation. In this way we have developed together a complete package for machine builders and end-users, the blue diode laser from Laserline with improved beam power, which made it possible to connect our our deflection unit. A true Hercules for laser production in electromobility. Our SUPERSCAN IV-30 has custom mirror coatings in the range 425-465 nanometers, which enable the user to utilise the full laser power of 2 kW and also attach a suitable welding sensor when a complementry hybrid mirror coating is used.”

Laserline has been testing the corresponding deflection unit in the course of this year. The SP-ICE-3 control card offers further benefits, which provides specific features for welding applications and is ideally matched to the LMDBlue. Thin copper foils can also be joined to other materials, such as steel and aluminium; and impressive results are achieved when butt welding and edge welding foils for batteries.

Advantages of the opto-mechanical deflection unit SUPERSCAN IV-30

SUPERSCAN IV-30 AT A GLANCE

- Control via SL2-100 protocol 20 bit or XY2-100 protocol 16 bit

- Significantly reduced power loss and lowest heat development through digital PWM output stage

- High dynamics and speeds for highest possible productivity in MOTF applications

- Additional welding sensors when a special hybrid mirror coating is used

- 30 mm aperture

WELDING OF ELECTRICAL CONTACTS: RELIABLE PROCESS WITH SCANNING OPTICS

- Collimation and focusing matching laser Scanner

- Spot @ 800 W 450 μm

- Spot @ 1500 W 600 μm

- Working distance > 180 mm

- Working field 50 x 50 mm2

The evaluation of feedback signals of the deflection unit reduces the error rate in the long term

The Laserline company

Laserline was founded in 1997 by Dr. Christoph Ullmann and Dipl.-Ing. Volker Krause. How did this come about? The two technology pioneers were convinced that they could use the laser diode that had been known since 1960 as a basis for developing an alternative radiation source for industrial laser processing – the diode laser. Initially, the project was hardly taken seriously since the single diode seemed to be too weak as a component for an industrial laser. However Ullmann and Krause stayed true to their vision.

What started off as a small team in the technology centre in Koblenz in Germany is the epitome of industrial laser technology today. Since 2002, the Laserline headquarters are on the approx. 15,000 qm company premises in Mülheim-Kärlich. Today, the company employs more than 340 people, who work in state-of-the-art production sites and have already received numerous awards for their innovations.

Image: Webpage Laserline

The fact that the high-performance lasers from Laserline, in particular the blue high-power diode laser in combination with our deflection unit, are in the meantime playing a key role in electromobility is due to our common development and research work, which bundles our forces again and again.

Dr. Philipp Schön, CEO RAYLASE

THE BOTTOM LINE:

In the context of increasing demand for environmentally conscious production processes also in the field of electromobility, intelligent laser systems comprising a blue diode laser PLUS optomechanical deflection unit, such as the comprehensive LASERLINE + RAYLASE package, not only enhance the versatility and quality of copper; they also improve the Co2 footprint. After all, the highly reflective material copper can - in contrast to infrared lasers - compensate the low power of the blue laser with its high absorption values.

For battery manufacturers, mechanical engineers, and end users all over the world, this means: Achieving a lower Co2 emission with lower energy consumption, while significantly improving quality in the production of small electric motors, power electronics and batteries.